Mint harvest winding down

Published 7:11 am Wednesday, October 3, 2007

HERMISTON – The pungent fragrance of mint permeates the air inside J.S.H. Farms’ mint processing facility along Highway 37.

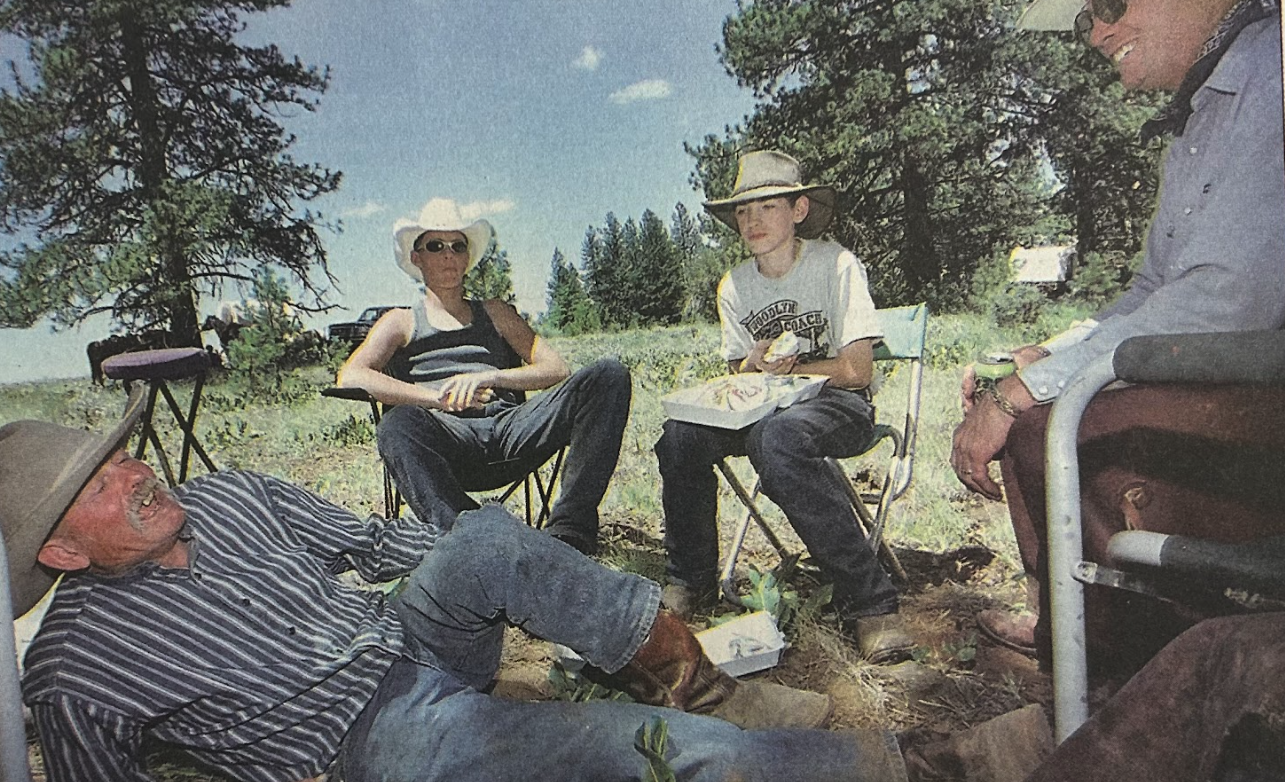

Plant manager Lester Chizek, with help from Jason St. Hilaire, monitors the constant traffic of mint-filled vans to and from the plant, and the processing that distills mint oil from the harvest.

J.S.H. Farms, started by Jason’s grandfather, Jim St. Hilaire, has 20 of the 38-foot-long, double-axle enclosed trailers. The operation has seven trailer stalls outside the still that can be used at once.

In the field, two workers pull the vans behind the mint choppers as they cut the crop and blow about 16 tons into each van, filling them two-thirds to three-quarters full. Five drivers take turns pulling the loaded trailers to the mint still and returning empties to the fields.

“The main cooking element is steam,” Chizek said. “We inject steam into the trailer.”

Because the vans are enclosed, the mint cooks inside and the mint-oil-laden steam flows through pipes into the plant, where it’s condensed. The mint oil rises to the top, is extracted from the water and flows into 55-gallon galvanized drums. Chizek estimated each trailer load of mint produces three-fourths to one 405-pound drum of oil.

Jason St. Hilaire said the farm uses 1,000 gallons of water per minute from the Columbia River and heats it in four natural gas-fired boilers. Steam enters the trailers at about 20 pounds per square inch and enters the still at about 200 degrees Fahrenheit. Chizek said it takes more than two hours to “cook” each trailer load.

Once the process is completed, a driver connects a tractor to the empty van and takes it to a tipper, where it’s cooked contents are dumped and piled. The St. Hilaires use the organic material as fertilizer on their crops.

Jason’s father, Matt St. Hilaire, J.S.H. Farms’ operations manager, said the farm is just finishing its second and last mint cutting for the year.

“The majority of the mint we grow is double cut,” he said.

Farm workers usually begin their first cutting the last week of June and finish by the end of July. In mid-August, they turn their attention to “baby fields” of mint that were planted the year before.

“Some of the baby stuff we plant in the fall we’ll double cut next year and some becomes root stock,” Matt said.

J.S.H. Farms also cuts some of its peppermint for tea, which involves combining it instead of cutting it with a swather, then chopping and distilling it.

Growing mint for tea is a more exact science, Matt said, especially guarding against chemical drift from neighboring fields.

“Certain chemicals you can’t use on those fields,” he said. “We’re pretty careful.”

Farm workers begin the second harvest about the first of September and usually finish at the end of the month, but this year the end of the harvest stretched into October.

Jim St. Hilaire began growing mint in the area in 1972 and established his distillery two years later. Today the operation is under control of four of his sons, Carl, Ron, Matt and Jeff.

Jason, one of the eldest grandchildren, joined the operation this summer after finishing high school in Hermiston. Chizek, who has worked for the St. Hilaires five years, calls Jason his “right arm” in the ever-changing process.

“I still learn every day,” Chizek said.

By KARI MAIOCCO

of the East Oregonian

Hermiston – Workers at J.S.H. Farms, operated by the St. Hilaire brothers, harvest three varieties of mint each year. The family leases more than 6,000 acres in Washington and Oregon, said Matt St. Hilaire, operations manager.

The St. Hilaires plant native spearmint, scotch spearmint and peppermint. Native spearmint is hardier than scotch spearmint, but not as valuable, he said.

Mint still manager Lester Chizek said J.S.H. Farms sells the oil to pharmaceutical and candy manufacturers. The top three buyers of J.S.H. Farms’ mint are I.T. Carlson in Lacey, Wash.; Labbeemint in White Swan, Wash., and A.M. Todd Co. in Kalamazoo, Mich.

Buyers use mint leaves for tea and mint oil to flavor toothpaste, mouthwash, gum and, of course, peppermint candy canes at Christmas.

“The end users blend the oils to get the flavor they’re looking for,” St. Hilaire said.